The Role of Annual Delivery Plans in Efficient CO₂ Terminal Design & Operations

- Systems Navigator

- Jul 31, 2025

- 2 min read

The Annual Delivery Plan (ADP) is essential for the reliable and efficient operation of CO₂ terminals. It serves as a planning, coordination, and communication tool that supports the long-term viability of carbon capture and storage (CCS) projects — a key part of many countries' climate goals.

What is an Annual Delivery Plan?

A logistical and operational plan used by facility operators and stakeholders.

Usually developed on a yearly basis, but reviewed and updated periodically.

Includes key components such as:

Forecasted volumes of CO₂ to be handled.

Schedule of incoming and outgoing shipments (by ship, pipeline, or truck).

Maintenance windows and outages.

Capacity planning and storage utilization.

Safety, environmental, and compliance requirements.

How is an Annual Delivery Plan used for CO₂ terminals?

Terminal Design

Determine the optimal tank size.

Assess the feasibility of additional emitters/lifters.

Quantify the added value of allowing lending and borrowing.

Evaluate the impact of different fleet mixes, ship capacities and roundtrip times.

Test and evaluate multiple (contractual) lifter rules.

Assess the impact of different emitter profiles.

Volume Planning

Forecasts the quantity of CO₂ expected from capture sources (e.g., power plants, industrial facilities).

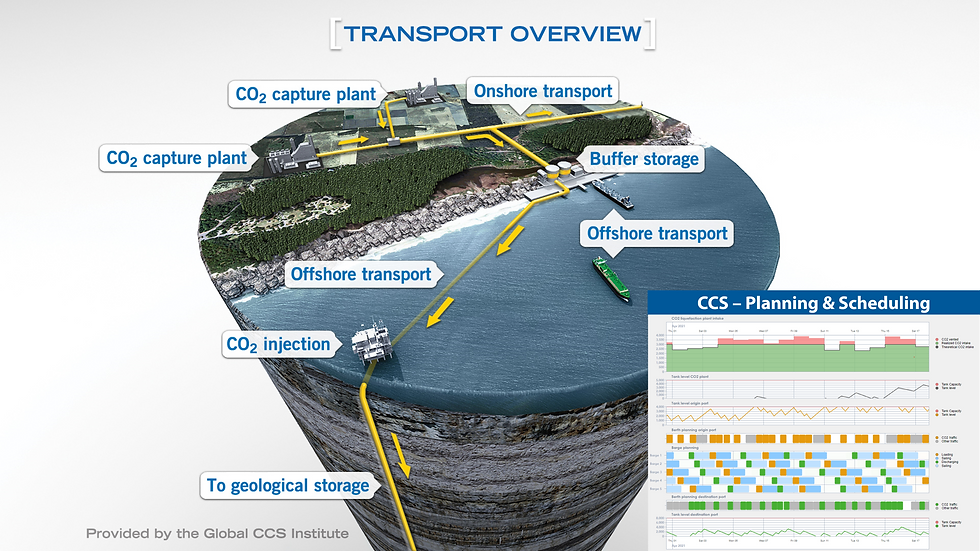

Plans how and when the CO₂ will be received, stored, and shipped (e.g., to offshore storage sites).

Scheduling Operations

Coordinates ship arrivals and departures if CO₂ is transported by sea.

Plans pipeline injection schedules for onward transport or storage.

Maintenance Coordination

Schedules preventive maintenance to avoid operational disruptions.

Aligns with low-activity periods to minimize downtime impact.

Stakeholder Alignment

Serves as a reference for all parties involved (capture partners, transport providers, regulators).

Ensures everyone is on the same page regarding responsibilities and timelines.

Risk Management & Contingency Planning

Identifies potential bottlenecks or risks (e.g., storage overcapacity, delays).

Includes fallback procedures and buffers.

✅ Why is having a robust Annual Delivery Plan important for CO₂ terminals?

Operational Efficiency: Helps ensure smooth, conflict-free logistics and minimizes idle time or excess storage.

Capacity Management: Prevents overfilling or underutilization of terminal storage.

Regulatory Compliance: Documents and demonstrates compliance with safety and environmental regulations.

Financial Planning: Informs budgeting, cost forecasting, and investment decisions.

Decarbonization Strategy: Supports broader carbon management objectives by ensuring reliable CO₂ transport and storage.

Operational Variability: minimize the impact of sailing delays, customer outages, fluctuations in CO₂ availability, mechanical failures

At Systems Navigator, we recognize that operating a CO₂ terminal isn’t just about infrastructure—it’s about precision, coordination, and control. That’s why we’ve developed a specialized Annual Delivery Plan (ADP) software solution, tailored to the unique challenges of carbon capture and storage (CCS) logistics.

Built on years of industry expertise, our platform enables terminal operators to plan and manage CO₂ volumes, optimize capacity, and align stakeholders—all from a single, intuitive interface. Leading companies like Air Liquide and Fluxys trust our solutions to power their operations, reduce risk, and support their decarbonization goals.

As CCS networks expand, a robust planning system is no longer optional—it’s essential.

👉 Get in touch today to learn how our ADP software can support your CO₂ terminal project—from concept to full-scale operation.

Comments